High-temperature alloys are metals designed to maintain their strength, shape, and resistance to corrosion even when exposed to extreme heat (often above 1,000°F / 538°C).

The most common types are nickel-based, cobalt-based, and some iron-based alloys.

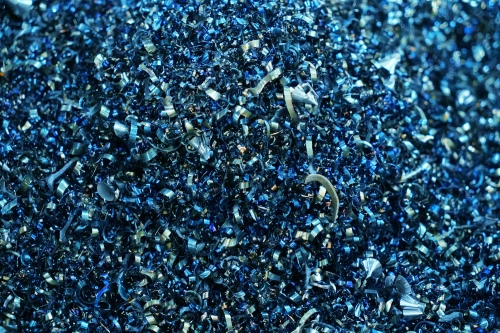

Although these alloys make up a tiny fraction of scrap volume, they’re among the most valuable because of the rare metals inside.

Some areas you will often find hi-temp alloys is the aerospace & aviation industry. Jet engine turbine blades, rocket engines, and exhaust systems will often have these alloys in them. The power generation industry will use hi-temp alloys in gas turbines, nuclear plants, and heat exchangers. Chemical plants, furnaces, and even medical implants will use hi-temp alloys because of their resistance to both heat and corrosion.

Some interesting facts about hi-temp alloys:

• They don’t slowly deform under constant stress at high temperatures like regular metals do.

• While regular steel loses much of its strength above 800°F, hi-temp alloys can remain tough at more than 2,000°F.

• The turbine blades in a jet engine spin at up to 12,000 RPM in air hotter than a blowtorch — all thanks to nickel-based alloys.

• NASA uses high-temp alloys in rocket engines, where materials must survive 3,000°F (1,650°C) conditions.